Flexible Connectors

BFM® fitting is the global leader in flexible connector technology, with the distinctive snap-in, flexible connector and spigot system that eliminates the problems associated with old-style hose clamp connectors.

The Unique Snap-fit Flexible Connector System

BFM® fitting is the global leader in flexible connector technology, with the distinctive snap-in, flexible connector and spigot system that eliminates the problems associated with old-style hose clamp connectors.

WHAT IS BFM FITTING SYSTEM

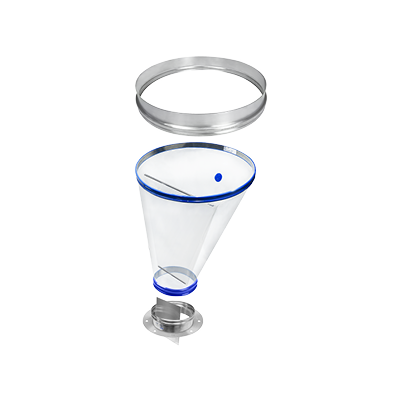

The BFM® fitting system is a unique flexible connector design that ensures there is no product loss in your processing.

The system generally fits between two pieces of machinery, either where a stationary machine connects to a moving one, or where access to product flow is needed.

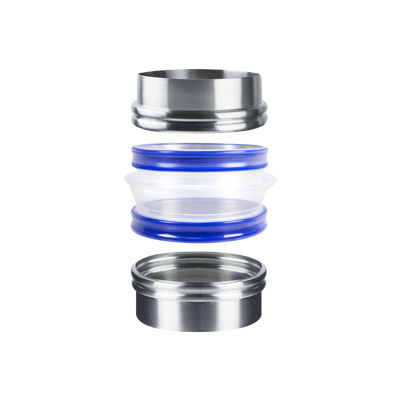

It comprises two steel adaptors called spigots that are welded to your tube or equipment and a snap-fit flexible blue-band connector that sits on the inside of the shaped portion of the two spigots, holding it securely in place.

Advantages of BFM Fitting System

CLEANER

Our BFM® flexible connectors are cleaner due to their unique blue band, a snap-fit design that closes from the inside. This enables a 100% sealed system that:

- Prevents product leakage

- Stops product build up, lowering contamination risk

- Eliminates dust

- Eases flushing

That’s why leading manufacturers trust BFM® to maintain the hygiene of their plants.

SAFER

Bulk processing plants have many situations and equipment where staff health and safety can be compromised.

Flexible connections between machinery can be a location for safety issues with potential dust leakage and the possibility of combustible dust explosions being a major concern.

The BFM® fitting flexible blue band connector system provides you with peace of mind that you’re improving safety for your staff.

EFFICIENT

When your flexible connectors tear or leak constantly, the efficiency of your production line reduces dramatically.

There’s downtime needed to replace the connector, and labour costs in cleaning up product spillage. And then, of course, there is the cost of the wasted product itself.

To improve your operational efficiency, you need to have durable, quality flexible connectors that last the distance and perform consistently, so that your production can continue without interruption.

QUICK CHANGEOVERS

When your flexible connectors tear or leak constantly, the efficiency of your production line reduces dramatically.

There’s downtime needed to replace the connector, and labour costs in cleaning up product spillage. And then, of course, there is the cost of the wasted product itself.

To improve your operational efficiency, you need to have durable, quality flexible connectors that last the distance and perform consistently, so that your production can continue without interruption.

IMPROVED HYGIENE

There’s no product build-up and easy flush through for cleaning provides a much more hygienic connection solution than clamped products where crevices can breed bacteria

REDUCED DOWNTIME

Faster changeovers, longer-lasting materials and less dust leakage mean there is significantly less lost production time for connector replacements and clean-ups with BFM® fittings

BETTER HEALTH & SAFETY

No tools required for installing standard BFM® connectors, plus less dust escaping into the plant combine to make a healthier and safer environment for staff.

NO PRODUCT LOSS

The 100% seal and the durable nature of the connectors mean no valuable product escapes during normal production and no spillage due to connectors tearing.

EXPLOSION RESITANT

The snap-fit internally seated cuff and spigot design seals tighter under pressure and the Seeflex range of connectors have been explosion tested in excess of 60kPa.

REGULATORY COMPLIANT

BFM® fitting products have been independently tested and conform with the leading internationally recognised health and safety legislation.

MORE DURABLE

The materials and design of the BFM® fitting connector system are extremely long-wearing and durable so they don’t need to be replaced as often as other connectors.

STREAMLINES INVENTORY

The BFM® fitting system simplifies and streamlines inventory control, improves supply chain sustainability and the standardized, exact sizes ensure a perfect fit every time.