Jet Sream Mixers

In process engineering, mixing refers to the combination of substances in a single or multi-phase system.

YTRON JET STREAM MIXER

The mixer, which creates a slow current in the liquid vessel, cannot provide sufficient micromixture. In addition, a mixer that rotates the liquid in the liquid vessel as a single mass in the vessel cannot mix the upper and lower layers of this liquid into each other.

WORKING PRINCIPLES

- The principle of the jet stream mixer is based on the rotor-stator system.

A fast rotating rotor (special type of impeller) creates a direct (guided) flow of liquid. - A guiding wall surrounds the rotor.

- This guide wall directs the liquid flow towards the bottom of the liquid vessel.

Vortex formation in the liquid vessel and thus mass rotation of the liquid in the vessel is prevented. - The liquid flow directed to the bottom of the liquid vessel is directed upwards from the bottom of the vessel.

- From the surface, it again directs towards the bottom of the liquid vessel.

In this way of movement, the entire liquid vessel becomes completely mixed and homogeneous.

ABOUT THE MIXING TECHNOLOGY

- In mixing technology, we divide the mixture into two: micro and macro.

- Micromixing defines turbulence that reaches even the smallest particles and ensures the formation of a perfectly homogeneous structure even in the smallest mixing volume.

- Macro mixing, on the other hand, circulates and homogenizes the entire volume without leaving any dead space inside the mixing vessel.

- The ideal situation is to get good macro mix and also good micro mix.

ADVANTAGES OF JET STREAM MIXER

- It does not return the contents of the liquid vessel as a single mass.

- There is absolutely no sedimentation in suspensions.

- There is no air penetration from the surface.

- Thanks to the homogeneous mixing effect, precise mixing is achieved.

- The rotor system is not exposed.

APPLICATIONS OF JET STREAM MIXERS

- Ytron Jet stream mixers are used in all branches of the chemical industry, pharmaceutical production, food industry and cosmetic products.

- The machines are designed according to the specified final product specifications. Separate and special designs are made for applications in hygiene and sterile areas, to other applications such as wastewater treatment systems.

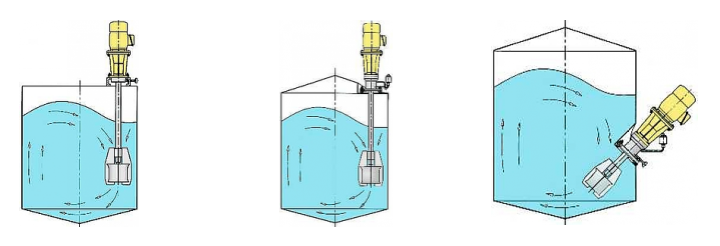

- Jet stream mixers are used for homogenization, dispersion, suspension preparation and emulsion preparation, crystallization, deaeration, dissolving, and increasing the rate of heat exchange on the walls of the liquid vessel. It can be fixed directly onto a tank or mounted on a mobile carrier. Can be mounted sideways on large liquid vessels.

- Jet stream mixer should be used wherever a truly homogeneous mixture is desired.

- One advantage of the Jetstream mixer is that it does not require additional assembly. For example, there is no need to place breakwaters in the liquid vessel.

- The mixing effect is so efficient that; A small mixer is sufficient to keep large volumes in constant motion. (such as milk stock tanks, crude mineral oil tanks)