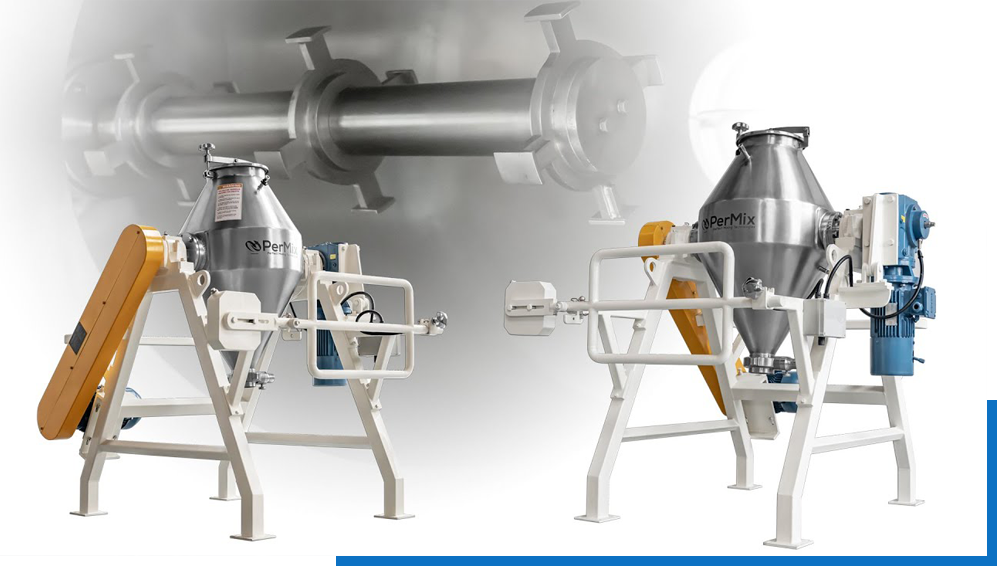

Powder Mixers / Blenders

PerMix powder mixers lead the industry in innovation, performance and quality. Our powder mixers include ribbon mixers, double shaft paddle mixers, plow mixers, paddle mixers, conical mixers and more…

Permix Powder Mixers and Blenders

PerMix powder mixers lead the industry in innovation, performance and quality. Our powder mixers include ribbon mixers, double shaft paddle mixers, plow mixers, paddle mixers, conical mixers and more… Our powder mixers are available in horizontal or vertical mixer configuration.

From laboratory size to large industrial size; Its volume varies between 1 liter and 30,000 liters. If necessary, larger mixers can also be produced specifically for the customer.

PerMix has been leading the industry in powder mixing since 1954, building some of the biggest brands known in the industry, as well as engineering for today’s needs while keeping the demands in mind, meeting the needs of up-and-coming brands.

PERMIX PTP SERIES PADDLE MIXERS

PerMix PTP series Paddle Mixers are an innovative design derived from the well-known Plow Mixers (or Plowshare Mixers, Plow Mixers). The Shovel provides the same mixing performance as the Plow but requires much less power consumption. Due to less rotational speed of shovels, the wear of mixing element for Shovel is also less than that of Plows. Additionally, PerMix Paddle Mixers have better performance when dealing with powder liquid mixture viscous/sticky materials such as slurry; This is because viscous materials can be stripped from plow-type mixing elements but not from paddle-type mixing elements.

Compared to traditional Ribbon Mixers, the mixing performance of Paddle Mixers is very superior. It can mix material more aggressively and moves more material in a single rotation because the uniquely designed blades are more curved than the ribbons on a Ribbon mixer at the same power consumption.

The main difference between our PTP Vane Mixer and PTS Plow Mixer is the mixing element: PTS Mixer uses the plow-shaped element, while PTP Mixer uses the paddle element. PerMix PTP Paddle Mixers can be used, including but not limited to; for combining, fine mixing, dispersing, suspending, emulsifying, deaerating, annealing, accelerating chemical or physical reactions, granulating, breaking down agglomerates, etc. wherever Plow Mixers are used.

What Sets Our Paddle Mixers Apart?

1. Precision Engineering:

Our paddle mixers are crafted with precision and expertise. The design ensures thorough mixing, making it ideal for a diverse range of industries, from chemical to cosmetics, and pharmaceuticals to food processing

2. Versatility at Its Best:

Whether you’re dealing with powders, granules, or even sticky materials, our paddle mixers excel in handling diverse substances. The adaptable nature of our mixers makes them a go-to choice for industries with varied mixing needs.

3. Optimized Performance:

Experience unmatched efficiency with our paddle mixers. The mixing process is optimized to save you time and resources, enhancing overall productivity in your operations.

Key Features of Our Paddle Mixers:

Heavy-Duty Construction:

Our mixers are built to last. The robust construction ensures durability, even in the most demanding industrial environments.

User-Friendly Controls:

We understand the importance of simplicity in operation. Our plow mixers come with user-friendly controls, making it easy for your team to achieve precise results. From simple controls to fully PLC/HMI with recipe control

Customization Options:

Tailor our plow mixers to meet your specific requirements. We offer customization options to ensure that you get the perfect solution for your unique mixing needs.

- Vacuum

- Heating & Cooling

- Hazardous & Explosive areas

- Abrasive & Corrosive material options & more…

Industries We Serve:

- Pharmaceuticals: Achieve uniform blending of pharmaceutical powders with our advanced plow mixers.

- Food Processing: From spices to bakery ingredients, our mixers ensure consistency in every batch.

- Chemicals: Handle a variety of chemical substances with confidence, thanks to the versatility of our plow mixers.

PERMIX RIBBON MIXERS

Unveiling the Power of Ribbon Mixers: A Comprehensive Guide

In the dynamic landscape of industrial mixing, ribbon mixers stand out as versatile workhorses that play a pivotal role in various manufacturing processes. Whether you’re in the pharmaceutical, food, or chemical industry, understanding the ins and outs of ribbon mixers can significantly enhance your production efficiency. In this guide, we delve into the intricacies of ribbon mixers, exploring their functionalities, benefits, and applications.

What are Ribbon Mixers? Ribbon mixers, also known as paddle mixers, are a type of horizontal mixer distinguished by their double helical ribbon agitators. These agitators create a unique fluidizing action, ensuring thorough blending of dry, semi-dry, or moist materials. The design promotes consistent mixing and allows for a wide range of viscosities, making ribbon mixers an indispensable asset in various industries.

Double Helical Ribbon Design: The primary distinguishing feature of ribbon mixers, the double helical ribbon design, ensures a gentle but effective mixing process, preventing product damage while achieving homogeneity.

Versatility: Ribbon mixers are highly versatile and can handle an extensive range of materials, including powders, granules, pastes, and more. This adaptability makes them suitable for diverse industries.

High Efficiency: With their efficient mixing mechanism, ribbon mixers reduce blending time and energy consumption, contributing to cost-effective and streamlined production processes.

Customization Options: Manufacturers often offer customization options, allowing businesses to tailor ribbon mixers to their specific requirements, such as capacity, material type, and discharge methods.

Applications

Food Industry: Ribbon mixers play a crucial role in the food industry, blending ingredients for products like confectioneries, cereals, and snack foods, ensuring a consistent taste and texture.

Pharmaceuticals: In pharmaceutical manufacturing, ribbon mixers are used for blending powders for medications, vitamins, and supplements, meeting stringent quality standards.

Chemical Processing: Ribbon mixers are employed in chemical processes, facilitating the homogenous blending of various chemicals and ensuring the uniformity of the final product.

Benefits of Ribbon Mixers

Consistent Quality: The gentle mixing action of ribbon mixers ensures a uniform blend, maintaining product quality and meeting industry standards.

Time Efficiency: Ribbon mixers reduce processing time, enhancing overall production efficiency and allowing businesses to meet increasing demand.

Cost-Effective: The efficient mixing process contributes to energy savings, making ribbon mixers a cost-effective solution for manufacturers looking to optimize their operational expenses.

Ribbon mixers, with their innovative design and multifaceted applications, have become indispensable in modern manufacturing. As industries continue to evolve, investing in ribbon mixers can be a strategic move to enhance productivity, ensure product quality, and stay competitive in a dynamic market. Explore the possibilities of ribbon mixers and elevate your production processes to new heights.

PERMIX PLOW MIXERS

What Sets Our Plow Mixers Apart?

1. Precision Engineering:

Our plow mixers are crafted with precision and expertise, featuring easily accessible doors for maintenance and cleaning. The design ensures thorough mixing, making it ideal for a diverse range of industries, including those dealing with powders, granules, and solids, from chemical to cosmetics, and pharmaceuticals to food processing.

2. Versatility at Its Best:

Whether you’re dealing with powders, granules, solids, liquids, or even sticky materials, our plow mixers excel in handling diverse substances. The adaptable nature of our mixers makes them a go-to choice for industries with varied mixing needs.

3. Optimized Performance:

Experience unmatched efficiency with our plow mixers. The mixing process is optimized to save you time and resources, enhancing overall productivity in your operations.

Key Features of Our Plow Mixers:

Heavy-Duty Construction:

Our mixers are built to last. The robust construction ensures durability, even in the most demanding industrial environments.

User-Friendly Controls:

We understand the importance of simplicity in operation. Our plow mixers come with user-friendly controls, making it easy for your team to achieve precise results. From simple controls to fully PLC/HMI with recipe control

Customization Options:

Tailor our plow mixers to meet your specific requirements. We offer customization options to ensure that you get the perfect solution for your unique mixing needs.

- Vacuum

- Heating & Cooling

- Hazardous & Explosive areas

- Abrasive & Corrosive material options

- & more…

Industries We Serve

Pharmaceuticals: Achieve uniform blending of pharmaceutical powders with our advanced plow mixers.

Food Processing: From spices to bakery ingredients, our mixers ensure consistency in every batch.

Chemicals: Handle a variety of chemical substances with confidence, thanks to the versatility of our plow mixers.

Why Choose PerMix?

Proven Track Record: We have a solid track record of providing reliable mixing solutions to industries worldwide.

Exceptional Customer Support: Our dedicated support team is always ready to assist you with any queries or concerns.

Innovation at Its Core: Stay ahead of the curve with our innovative plow mixer designs that incorporate the latest technological advancements.

PERMIX VACUUM MIXER & DRIER

What Sets Our Plow Mixers Apart?

1. Precision Engineering:

Our plow mixers are crafted with precision and expertise, featuring easily accessible doors for maintenance and cleaning. The design ensures thorough mixing, making it ideal for a diverse range of industries, including those dealing with powders, granules, and solids, from chemical to cosmetics, and pharmaceuticals to food processing.

2. Versatility at Its Best:

Whether you’re dealing with powders, granules, solids, liquids, or even sticky materials, our plow mixers excel in handling diverse substances. The adaptable nature of our mixers makes them a go-to choice for industries with varied mixing needs.

3. Optimized Performance:

Experience unmatched efficiency with our plow mixers. The mixing process is optimized to save you time and resources, enhancing overall productivity in your operations.

Key Features of Our Plow Mixers:

Heavy-Duty Construction:

Our mixers are built to last. The robust construction ensures durability, even in the most demanding industrial environments.

User-Friendly Controls:

We understand the importance of simplicity in operation. Our plow mixers come with user-friendly controls, making it easy for your team to achieve precise results. From simple controls to fully PLC/HMI with recipe control

Customization Options:

Tailor our plow mixers to meet your specific requirements. We offer customization options to ensure that you get the perfect solution for your unique mixing needs.

- Vacuum

- Heating & Cooling

- Hazardous & Explosive areas

- Abrasive & Corrosive material options

- & more…

Industries We Serve

Pharmaceuticals: Achieve uniform blending of pharmaceutical powders with our advanced plow mixers.

Food Processing: From spices to bakery ingredients, our mixers ensure consistency in every batch.

Chemicals: Handle a variety of chemical substances with confidence, thanks to the versatility of our plow mixers.

Why Choose PerMix?

Proven Track Record: We have a solid track record of providing reliable mixing solutions to industries worldwide.

Exceptional Customer Support: Our dedicated support team is always ready to assist you with any queries or concerns.

Innovation at Its Core: Stay ahead of the curve with our innovative plow mixer designs that incorporate the latest technological advancements.