Homogenizer

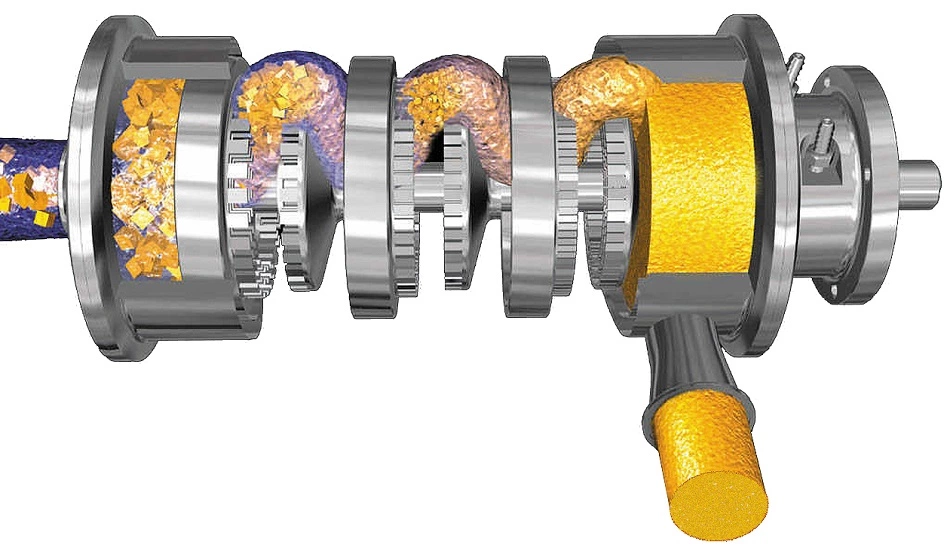

One or more liquid phases, as well as unsuspended particles, are passed by a forced-feed passage through the rotor-stator-system. The In-line-principle affects a defined and reproducible application of shear forces.

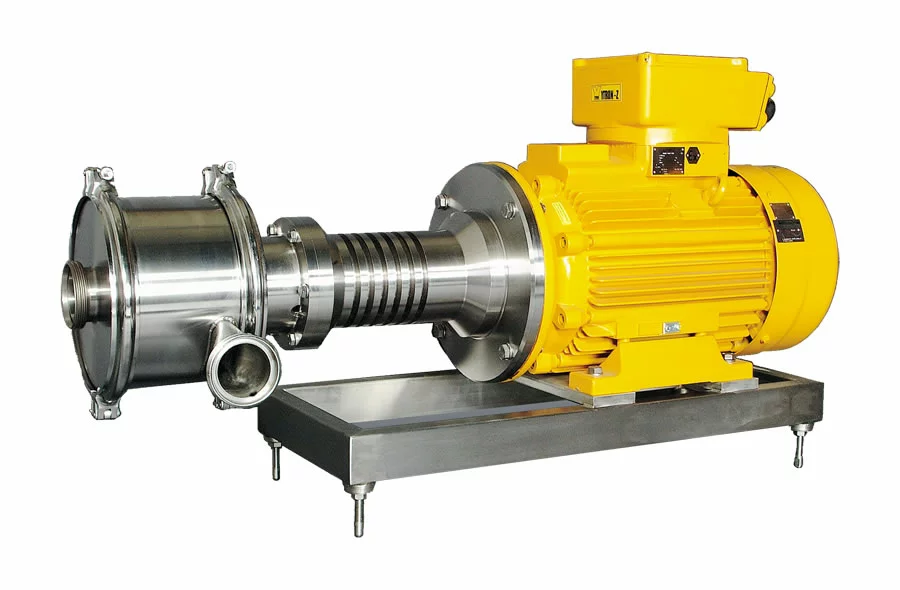

YTRON HOMOGENIZER

One or more liquid phases, as well as unsuspended particles, are passed by a forced-feed passage through the rotor-stator-system. The In-line-principle affects a defined and reproducible application of shear forces.

With the parameters of slot width, number and distance of the shear slots, number of rotor-stator-sets used, rotational speed and flow rate, the desired dispersing or homogenizing effect, can be infinitely adjusted.

Conventional batch processes often require recirculation and lead to a localised over-shearing of the products. This also lead irregular treatment of the batch. In contrast, the YTRON-Z ensures a homogeneously and reproducibly dispersed product in a single pass.

YTRON-Z INLINE HOMOGENISATOR

- Homogenizing

- Wet grinding

- Stretching® of fluids with high shear

Special features:

- To be used for dynamic mixing, diluting, emulsifying, desagglomerating

- Homogenizing of liquids

- Individually adjustable by selecting specific rotor/stator combinations.

- Dispersing and pumping effect combined in one unit.

- Hygienic execution for use in Food and Pharma applications

- Motor power: 1.5 – 132 kW

YTRON-Z INLINE HOMOGENISATOR

TYPICAL APPLICATION EXAMPLES

- De-agglomerating

- Emulsifying

- Chemical reaction

- Homogenising

- Wet milling

- STRETCHING®

- Modification of texture and adjustment of viscosity

- Foaming, Aerating

SOME ADVANTAGES OF USING YTRON-Z IN FOOD APPLICATIONS

- Improved product quality and shelf life stability

- Reduced production times due to a single pass operation

- Reproducibility of results

- Saving of energy, materials and process time when compared to batch procedures and conventional processes

- Flexibility due to interchangeable dispersion tooling

- Improved rheological properties, mouth-feel and texture

Application Examples

- Bitumen

- Tomato Ketchup (cold and hot break)

- Creams and lotions

- Fruit juices

- soft drinks

- Mayonnaise

- Medical solutions and dispersions

- O/W and W/O emulsions

- Perfume oil and aromatic products

- Pesticides

- S.L.E.S ( continuous diluting)

- STRETCHING® of yoghurt and fromages frais

- STRETCHING® of thickener slurries

- Soups and sauces

- and many more…

YTRON-ZHV HOMOGENIZER

High Shear Inline Homogenizer for emulsification or wet milling

A typical solution for many applications in the field of Food-, Pharmaceutical, Chemical and Cosmetic Industries is the use of a High Pressure Homogenizer. YTRON-ZHV may be a real alternative for your process, offering an important added value.

YTRON-ZHV is designed for peripheral speeds of up to 60 m/s. Several different configurations are available.

In a good number of applications, the effect achievable with YTRON-ZHV significantly exceeds the typical limits of toothed rotor/stator systems.

YTRON-ZP SHEAR PUMP

Special advantages:

- To be used for dynamic mixing, diluting, emulsifying, desagglomerating

- Homogenizing of liquids

- Individually adjustable by selecting specific rotor/stator combinations.

- Dispersing and pumping effect combined in one unit.

- Hygienic execution for use in food and pharma applications